Realizing sustainability is key

Before founding ETB Global, Noah Vladimir Hirsch Trembovolsky (now Co-founder and CEO) worked in a distribution company for the сonsumer and industrial machinery that was expanding across Eastern Europe. Although the job provided a comfortable living, he felt something was missing: the work lacked real impact. Noah increasingly felt drawn to tackling challenges that were complex, meaningful, and globally relevant.

Around 2013, a friend introduced him to a group of catalysis scientists working on a method to produce butadiene from ethanol, including Dr. Vitaly Ordomsky (now at the University of Lille) and Dr. Vitaly Sushkevich (now at PSI/ETH Zurich). Initially, the motivation was pragmatic. Global butadiene supply was volatile, prices were high, and the industry was in need of alternative production routes. Noah recognized a clear gap in the market.

Over time, the sustainability dimension became equally important. He realized that the global butadiene market amounts to roughly 15 million tonnes per year, with an estimated value of €25 billion, while conventional production generates over 13 million tonnes of CO₂ annually. Achieving true impact, Noah concluded, would require innovation not only on an economic level, but also in terms of sustainability.

“Our insight was simple: if you want to decarbonize these value chains, the replacement molecule must be chemically identical—a true drop-in. That principle still guides everything we do”

, explains Noah.By 2017, the team had built and operated a pilot facility, with reactor demonstrations witnessed by a major German chemical company. In 2020, Noah relocated with his family to Geleen in the Netherlands to establish ETB Global at Brightlands Chemelot Campus — one of Europe’s most important chemical industry hubs.

The timing was deliberate. Downstream industries such as tire and plastics manufacturing were facing increasing pressure to decarbonize, yet butadiene — a key building block for rubber and many plastics — remained almost entirely fossil-based. At the same time, the European market was actively seeking sustainable solutions to the highly polluting production of commodity chemicals, and Chemelot Campus had set the goal of becoming the cleanest chemical hub in Europe by 2035. In this context, ETB chose to grow its company and technology in Limburg, the Netherlands.

Today, ETB Global operates with a core team of six highly experienced professionals. The scientific founders collectively hold hundreds of publications and multiple patents in catalysis, with key contributors such as Dr. Vitaly Ordomsky and Dr. Vitaly Sushkevich continuing to support the company’s development. Noah brings more than 15 years of experience in building businesses across multiple industries. He holds an MBA in Entrepreneurship from Kingston University and has completed executive education at Stanford.

On the industrial side, the company works with professionals who have extensive experience at leading firms such as DSM. The team includes chemical engineers and PhD-level specialists and is supported by strong industrial partnerships. BASF Major chemical company manufactures ETB’s catalyst at scale, while engineering partners support validation and process scale-up.

Beyond Noah´s personal challenge of relocating his family during the COVID-19 pandemic, the team faced additional hurdles. Scaling deep-tech chemistry is inherently complex, requiring significant capital, long validation cycles, and the trust of conservative industrial value chains that often operate on 20-year equipment lifetimes. The butadiene market itself is volatile, complicating long-term planning, while the European chemical industry faces pressure from energy costs, regulation, and evolving sustainability priorities. In response, ETB has pursued a phased scale-up strategy, with each validation milestone building confidence for the next stage.

About the name: ETB stands for Ethanol-to-Butadiene.

"We were not particularly creative — deliberately so. The name describes exactly what we do and reflects our ambition to make this process a global standard for sustainable butadiene production"

, elaborates Noah. Making butadiene renewable again

1,3-butadiene is a key building block for plastics, rubber, and other chemical materials. It is essential for producing many everyday commodity products, including tires, latex gloves, and toy building bricks. Today, over 95% of global butadiene production is fossil-based, as it is mainly derived as a by-product of petroleum steam cracking.

Historically, however, butadiene was first produced from ethanol, a route that was widely used before World War II. After the war, the chemical industry shifted toward petroleum-based production because it was more economical at the time. In recent decades, interest in ethanol-based butadiene production has re-emerged, driven by environmental concerns and the need to reduce dependence on fossil resources.

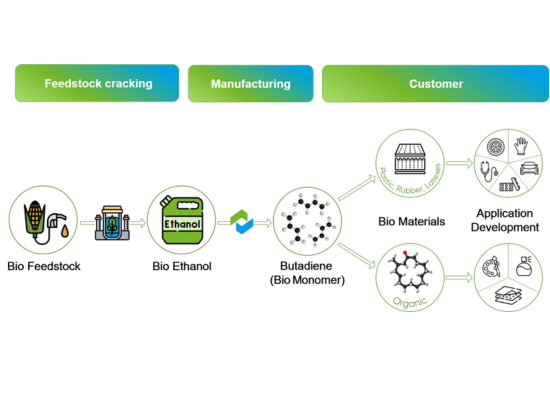

Noah and his team recognized that for ethanol-based production to become competitive again, significantly improved catalysts were required. ETB Global has therefore developed a patented one-step catalytic process that converts bioethanol directly into butadiene in a single reactor. The core innovation is a proprietary polyfunctional heterogeneous catalyst that enables more than fourteen reactions to occur simultaneously in one pass.

Most alternative approaches rely on a two-step process: ethanol is first converted into acetaldehyde, which is then reacted with additional ethanol to form butadiene. This requires two reactors, two catalyst systems, and more complex operations. In contrast, ETB’s catalyst enables these reactions to occur in a coordinated sequence without isolating intermediates, significantly simplifying the process.

The innovation focuses on the raw-material production stage, converting renewable bioethanol into a chemical building block. Bioethanol is an abundant and accessible feedstock, produced from corn or other plant materials, with relatively predictable pricing. Based on preliminary internal calculations using publicly available emissions data, the process is estimated to have a lifecycle carbon footprint approximately 70% lower than conventional fossil-based butadiene production. These estimates are indicative and will be evaluated through a full life-cycle assessment planned for future work. When powered with carbon-neutral energy, even greater emission reductions may be possible.

In addition to butadiene, the process generates valuable co-products, including green hydrogen, which can be stored and sold into other sustainable value chains. The single-step approach operates at lower temperatures than steam cracking, uses roughly one-third of the energy, and achieves high selectivity toward the target product.

Crucially, the butadiene produced is chemically identical to fossil-based butadiene. This enables a brownfield-first strategy: the product can be used immediately in existing rubber and plastics manufacturing without reformulation or requalification. Downstream manufacturers do not need to change formulations, customers do not need to adjust purchasing specifications, and end-of-life recycling pathways remain unchanged.

“This is deliberate: we believe sustainability only works at scale if it does not impose additional complexity on the value chain,”

explains Noah. Beyond environmental benefits, ETB’s technology improves supply security by enabling on-purpose butadiene production independent of steam cracker operations — addressing a structural shortage as European crackers shut down. The company estimates 30–40% lower capital intensity compared to two-step bio-butadiene processes, strengthening project economics. Socially, ETB’s projects support job retention in industrial regions undergoing economic transition.Finally, the catalyst can be regenerated in situ, meaning it can be cleaned and restored to its active form directly inside the reactor without removal. Together, these features allow sustainability benefits to cascade through the entire value chain — without requiring changes in manufacturing, distribution, use, or recycling.

Next up at ETB Global

ETB´s immediate focus is completing the validation campaign to achieve the next technology readiness level—the critical milestone for industrial credibility. They are working with specialized R&D partners to produce polymer-grade butadiene samples that downstream customers can test in their formulations. In parallel, ETB is advancing discussions with brownfield partners to identify integration opportunities for their first commercial facility.

Following validation, the young company plans to build their first commercial brownfield plant in the 10–20 kilotons per year (kta) range. This facility will generate revenue and operational data while demonstrating the technology at commercial scale. From there, they plan to scale to 100 kta flagship plants and ultimately license the technology globally. The long-term vision is to enable bio-based butadiene production wherever ethanol is available - e.g. the United States of America, Brazil or Asia. ETB aims to be the technology partner that makes this transition possible worldwide.

With their innovative approach, ETB Global, who joined the ISC3 Global Start-up Service as one of the Innovation Challenge finalists in Sustainable Chemistry and Climate Change in July 2025, actively contributes to SDG9 (Industry, Innovation and Infrastructure), SDG12 (Responsible Consumption and Production), SDG13 (Climate Action) and SDG17 (Partnerships for the Goals).