Valuable unexpected outcomes

Power2Polymers began in 2016 as a collaboration between RWTH Aachen University and an industry partner. The initial task force was commissioned to develop a more sustainable alternative to conventional polypropylene glycol (PPG) — a key component of plastic foams whose production relies heavily on fossil fuels. The aim was to integrate a novel building block to reduce the carbon footprint of novel PPG in everyday products.

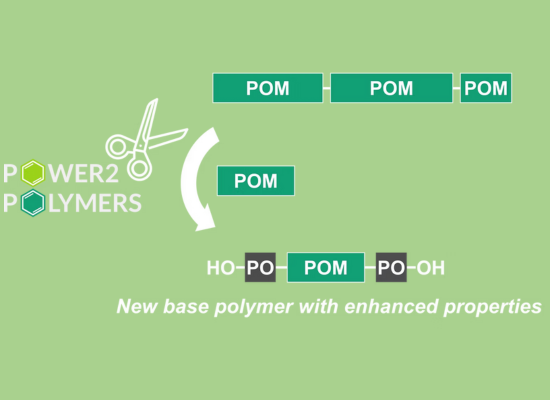

Although this research phase did not achieve the intended substitution, it led to an unexpected breakthrough: the development of novel polyoxymethylene-polyols (POM-polyols). Polyoxymethylene (POM) is an extremely stable but chemically inert material, previously only available in solid form — making it very difficult to integrate into polymer networks such as foams, coatings or adhesives. The team succeeded in linking POM with polyols (polymers rich in reactive hydroxyl groups), creating liquid POM-polyols that can be blended and reacted with other components.

While POM-polyols are not a drop-in replacement for PPG in mass-market applications, they bring significant advantages in specialty areas such as industrial adhesives, coatings, and lubricants. The intellectual property generated from this work — including ten patent families — was transferred to Power2Polymers, a spin-off from RWTH Aachen. Since then, the startup has been working with various industry partners to develop and commercialize the technology.

"For me personally Power2Polymers was also a great opportunity aiming for the demonstration that it is also possible to keep and develop a Made-in-Germany technology in the chemical industry in Germany also in tough times"

, explains Dr. Guido Schroer, Co-founder & CEO of Power2Polymers. According to Guido, the German chemical industry faces difficult conditions due to e.g. high energy costs and growing trade barriers. After completing his PhD in technical polymer chemistry and working as a consultant at the Boston Consulting Group, where he focused on sustainability and the chemical sector, he saw Power2Polymers as a way to combine his expertise with his entrepreneurial ambitions.

The founding team also includes RWTH Aachen alumni Dr. Tobias Riedl (CTO), who holds a PhD in technical polymer chemistry; Yannik Kohlhaas (COO), who is completing both a PhD in chemical engineering and an MBA, and oversees production and scale-up; and Dr. Harald Rubner (CFO), who joined after more than 30 years at Boston Consulting Group. Together with three additional full-time colleagues and working students, the team currently numbers 14.

The name Power2Polymers reflects the project’s original vision: building a value chain based on innovative raw materials. The startup uses methanol — produced from hydrogen and captured CO₂ — as a upstream raw material. The team believes this technology can play an important role in establishing a resilient and sustainable C1 value chain, helping to create a high-value outlet for green methanol.

Superior products – in performance and sustainability

Power2Polymer´s innovation are novel polymer materials for specialty applications like industrial adhesives and lubricants, as well as coatings for broad applications ranging from wood furniture over electronics to automotive. Via a patented process integrating POM into base polyols, it is possible to get the properties of POM, which is already used widely in the industry, in a liquid form. It was previously not possible to integrate POM into polyols. These can then be used for follow-on products with product-dependent enhanced properties. For industrial adhesives these advantages include, by example, shorter drying times, better material compatibility and better recyclability.

The resulting materials are, additionally, more sustainable in comparison to industry benchmarks. This is mainly because raw materials are used, that are less carbon intensive since they derive from renewable sources, mainly via methanol, which in turn is produced from CO2 and hydrogen or biomass. Thus, the resulting carbon footprint reduction of the materials is up to 60% compared to conventional polypropylene glycols (the current alternative to POM-polyols). The integration further leads to materials and products with better recyclability. Namely, this includes chemical recycling, adhesives that can be separated when needed, and mechanical recycling through extrusion — enabled by the improved compatibility of nonpolar packaging materials with a POM-polyol-based adhesive layer.

Furthermore, the implementation of the production of the novel polymer does not require a carbon-costly investment, as it can be integrated into existing value chains, which is a tremendous advantage towards commercialization. The problem that remains to be solved for this solution to become a highly sustainable alternative is the necessity of enough renewable methanol being available at an economically viable price. Based on current forecast this should be possible within the next years.

A crucial step for the start-up´s success was finding the right industrial and application partners for developing resulting products from their novel materials together. This included open communication, exchange, and the understanding of partners that initial samples might not be directly perfect and have to be jointly iterated and optimized.

"This feedback was and is crucial for us and we are very thankful for all our great partners. Only with them is it possible to learn, develop and implement the technology"

, states Guido. Power2Polymers collaborates with research institutes and with industrial partners across the entire value chain. Through these partnerships, they aim to commercialize more sustainable and higher-performing material alternatives.

Next up at Power2Polymers

The young company´s current focus is the development, implementation and commercialization of novel products, namely, but not limited to industrial adhesives, lubricants and coatings, together with industry partners. This includes testing of the materials as well as scaling, discussions on economics and confirmation of material benefits.

Aside from the aforementioned fields of focus, future and next steps include the expansion of their product portfolio towards more grades of POM-polyols, e.g. higher molecular weights, as well as additional products, e.g., functionalized short-chain POM-containing polymer building blocks like sustainable epoxides and di-isocyanates. Further fields include scaling, internationalization and moving from specialty products also towards commodities to implement carbon footprint reduction in a wider range of products.