Breathing new life into green wastes

Agricultural waste contaminates water and soil resources and increases local air pollution, which is of global environmental concern. Matan Dahan, CEO and co-founder of CannaRe, recognized the need to address this pressing issue during his studies in Sustainable Resource Management at the Technical University of Munich. Focusing on waste management and material flow, he also realized the enormous quantity of green waste that is actually produced, especially in cities with extensive green areas. Later, working in the Agricultural Engineering Department of the Israeli Agricultural Research Organization and private Agro-tech startups developing innovative water sensors, helped him to better identify industry needs for waste management solutions, specifically for agricultural and green urban waste.The very interesting insights matured in Matan and his longtime friend, mechanical Engineer Aviad Achrak (CTO) and led them to found CannaRe in late 2019. Later on, Dr. Rina Reznik (Chief Scientist) and Yuval Levy (Business Director) joined the CannaRe team as well.

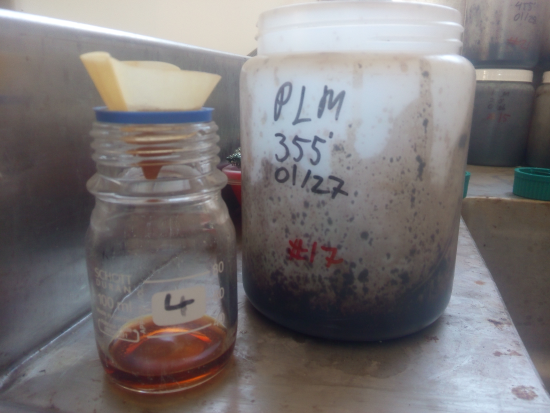

CannaRe has developed a thermo-chemical technology that allows the extraction of valuable chemical compounds. The latter come in the form of natural aroma and flavor ingredients derived from high volume biomass wastes and are generated at very distinct applied conditions in a closed environment, such as heat, pressure, and gas supply. The start-up uses municipal green waste such as trimmings of trees from the city’s green areas, waste from food production processes (e.g. fruit juice factory orange peels) or agricultural waste (e.g. stems and roots from agricultural plants) for raw material supply. CannaRe then transforms these biomass wastes into liquid, from which the desired chemicals can be extracted. The target chemical compounds from biomass wastes are polyphenols, which among other things, play an important role in the immune system of plants. CannaRe’s well-pondered treatment maintains the plant’s immune system and thus allows for the extraction of polyphenols that retain their precious chemical composition. Among the advantages of CannaRe’s innovation is that the treatment only takes about 3 hours, comes with almost zero by-products compared to other treatment alternatives, and requires low energy usage since the reaction is exothermic. This enables CannaRe to recycle produced gases for the treatment’s own energy supply. The remaining solid byproduct can then be applied to sustainable agriculture schemes. “The fact that the treatment is pretty fast enables us to do more repetitions, giving us the possibility of using a smaller reactor volume, so that our treatment plant can actually be mobile.”

And it is this mobility of their innovation that allows CannaRe to reduce logistic costs to a minimum, meaning only the transport cost to make their technology reach the biomass source, e.g. one farm after another. After the treatment, volume and weight of the input raw material shrinks to a minimum in the form of the precious obtained polyphenol containing liquid.