A self-taught product developer

The co-founders Charles Dimmler and Scott Franklin named their enterprise after the endangered Checkerspot Butterfly that is endemic to the Sierra Nevada mountains in California, where the start-up is based: “With a butterfly, you have exquisite elegance in how nature has evolved over billions of years to develop structure and function of materials that just perform perfectly. If you distil down our activities from a technology development perspective, we’re leaning into nature. Like in biomimicry, we’re coaching single cell organisms to produce distinct kinds of oils that lead to performance materials,” Dimmler says. In fact, tapping into nature’s vast potential of molecular building blocks has been Checkerspot’s mission ever since they first started in June 2016.

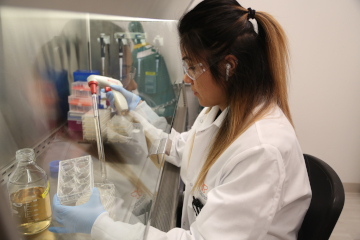

In its Berkeley headquarters, Checkerspot focuses on the molecular foundries and works with the microalgae in a fermentation based-system. Salt Lake City, in turn, is home to the Checkerspot Design Lab, where the rapid prototyping of materials and products deriving from the fundamental platform technology is addressed. During the last three and a half years, the start-up has grown substantially. From a founding team of 6 people, Checkerspot has now evolved into a team of 30 employees in its two units that are split between Berkeley, California and in Salt Lake City, Utah.

Exploring underserved markets

During the first oil crisis at the beginning of the 1970s, the US Department of Energy sponsored efforts to produce oil from microalgae in order to stay autonomous from unsecure imports. Scientists started to explore ways to accelerate that process but struggled with developing a cost-effective solution. In the 1990s, the human genome project constituted a revolution in biotechnologies: While it mainly focused on humane therapies and diagnostics, some researchers recognized that the newly found tools could also be deployed to produce algae-based oils in a cost-effective and competitive way. The yields and productivity started growing but in the early 2010s, oil prices dropped again and bio oil could not compete on the main market anymore. Charles Dimmler, however, recognized that there were certain applications of oil that had high value in the market. As an outdoor enthusiast, he went to a ski building workshop in Innsbruck, Austria, and found that all skiing brands used the same suboptimal performance materials that were initially designed for other sectors, like automotive and aerospace. Recognizing this market niche for superior performance materials, Dimmler partnered up with Franklin, and together they bred microalgae able to produce oil that exactly meets the material requirements of an alpine ski. And, thus, WNDR Alpine was born, the first animation of Checkerspot’s technology platform.

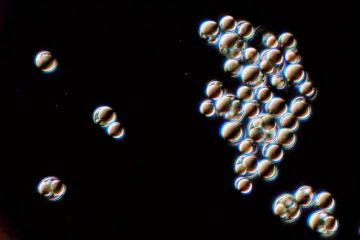

Great potential of microalgae

After 3.5 years since its foundation, Checkerspot is able to build and serve less toxic, environmentally safe and better-performing materials to the market, and it is striving to accomplish even more: The team is currently working on the use of non-fluorinated chemistries for textile finishes and waterproof textiles. Such chemistries are contained in almost anything we use, from packaging to furniture. Beyond this, microalgae also hold the potential of creating better, healthier types of triglycerides and oils for nutrition. However, in order to unleash the full potential of microalgae applications, Checkerspot cannot act alone. “Our vision is to work in partnerships, empower and provide innovative technology and tools in the hands of innovators, product developers and designers, so that together as a global community we solve societal challenges,” Dimmler explains.

Addressing the SDGs through Sustainable Chemistry

Through the development of its innovative performance materials, Checkerspot addresses multiple SDGs. “I truly believe that Checkerspot holds the potential to impact big societal challenges, ranging from climate change and its mitigation to thinking about alternative ways to be a good steward to the environment, and to getting away from the use of toxic chemicals,” Dimmler says. As all inputs for Checkerspot’s high-performance materials are bio-based and environmentally safe, the start-up supports responsible consumption and production (SDG 12). Moreover, by deriving oil from microalgae and replacing petroleum and vegetable oils, Checkerspot contributes to affordable and clean energy (SDG 7) and climate action (SDG 13).

Checkerspot was one of the first start-ups on-boarded to the ISC3 Global Start-up Service. The team joined the Service following their participation in the Investor Forum 2018, organized by the ISC3 in cooperation with Think Beyond Plastic and the Ellen McArthur Foundation. Since then, Checkerspot has been ranked among the next 50 companies to disrupt the world by "The Digest" and was nominated by ISC3 to be one of the Technology Pioneers 2020 at the World Economic Forum.