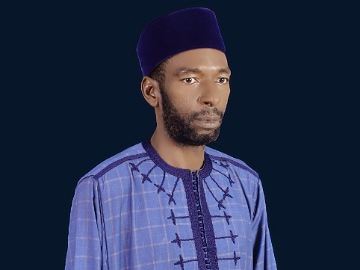

A self-taught product developer

Sani Nababa Abdulmumini, the founder of Paraexcel Global Ltd., started as an entrepreneur in a family business, operating a mining and solid minerals processing business supplying the ceramic, animal feed, fertilizer, and construction industries with basic raw materials like marble, limestone, and dolomite in lumps, chippings, powder or cut stones. As an entrepreneur with a strong interest in society and the local economy, he recognized the problem of post-harvest loss of farmers in Nigeria, which inspired him to devote his work to edible coating production in order to tackle this pressing issue. And so, Sani became a self-taught product developer and producer experimenting with biodegradable and bio diversified organic raw materials, partially coming from organic waste to develop a single edible coating formulation to extend the shelf life of fruits and vegetables. After a few years of research and experiments, in 2018 Sani came up with a viable product named Phytorbit that can help reduce post-harvest loss.

Fighting post-harvest loss with edible coatings

“Each year, one-third of the global food produced is lost due to post-harvest loss, while a total of 1.2 billion people go to bed hungry. The food that spoils or gets thrown away is enough to feed every hungry person on earth, with nearly 50% to spare. On the other hand, farm waste is expensive to dispose of and hard to manage profitably”, Sani explains. The agricultural sector in Nigeria employs the largest number of population and contributes with significant amount to Nigeria’s GDP. According to Sani: “Most of the agricultural products in the country supplied in excess during the harvesting period rot away, denying the farmers profitable returns on their labor and other resources invested in the farming, because there are no adequate storage facilities, and where there are, there is an incessant power outage.”

Thus, Paraexcel developed a chemical-free edible coating which extends the shelf life of fruits and vegetables by 2 to 3 times while it also helps to reduce post-harvest loss for farmers. The start-up uses organic raw materials and some organic waste streams, such as watermelon rind, hibiscus leaves, orange peel, and a host of other seeds and roots, which are all edible and safe for human consumption. The selected raw materials undergo an ozone hydroxyl cleaning process for sterilization and removal of germs, pesticides, and other impurities. Each of the selected raw materials gets processed to micro powder before preparing the final formulation. The formulation is highly soluble in water and dissolves easily. It is applied on fruits and vegetables by using one of two techniques – dipping or spraying. In any case, the first step to effectively apply Phytorbit is to specify an appropriate dilution level depending on the type and surface texture of a target fruit or vegetable. When sprayed on products or dipped in the solution, an invisible edible and protective coating is formed on the product that after drying serves as a barrier reducing the gaseous exchange between the coated product and the atmosphere. The coating also reduces weight loss of products, maintains freshness and firmness, and reduces spoilage during transportation and storage. Simultaneously, the edible coating has anti-microbial properties inhibiting the growth of microorganisms that accelerate the decaying process. The technology is patented and registered under the trademark “Phytorbit™”. The innovation has multiple times greater effects on shelf-life extension of fruits, vegetables, and tubers than refrigeration and drying techniques. Beyond this, it is also less costly, less energy-consuming, and less labor-intensive. The developed technology can be beneficial at any stage in the value chain of mentioned agricultural goods. And so, Paraexcel’s edible coating can be used by small and medium-scale farmers, large scale farmers, local and industrial processors, distributors, and consumers.

Next up at Paraexcel

Currently, Paraexcel is working on extending the range of fruits, vegetables and tubers on which Phytorbit can be applied. So far, Paraexcel offers edible coating for cassava, Irish potatoes, onions, and tomatoes, which are among the most important local agricultural goods. The start-up is mainly active in Nigeria, but - as their innovation is not bound to any specific climate conditions - their solution could become a global one. The sustainable and beneficial use of organic wastes to preserve fruits, vegetables and tubers not only helps to reduce post-harvest loss, thereby ensuring food security and progress toward zero hunger, but also reduces land and air pollution and contributes to climate change mitigation efforts, as food waste and post-harvest losses would end up in landfills, contaminating the natural environment. In this way, Paraexcel, who joined the ISC3 Global Start-up Service (GSS) in August 2020, actively contributes to SDG 2 (zero hunger), SDG 3 (good health and wellbeing), SDG 11 (sustainable cities and communities), SDG 12 (responsible consumption and production), and SDG 13 (climate action).