A tale of improving people’s lives through bravery and determination

The idea for “Theseus Development” was conceived, when Evans Nartey, a geological engineer, came together with two close friends and classmates to try to create a new type of material for the construction industry that, he had read about during his studies, called “geopolymers”. For three years the group of young engineers was experimenting and developing samples of this alternative to the common cement until they finally, produced a promising result. In 2023 the team emerged as one of the winners of the African Climate Innovation Challenge.

Evans´ motivation to become an engineer and his interest in the construction industry started way back in his childhood. When his mother got divorced and had no home of her own, Evans developed a dream to build her a house. Additionally, the early exposure to the construction industry came through Evans´ father, who was a builder. For these reasons, Evans chose to study engineering in college, to learn how to design and construct buildings. During his studies, Evans stumbled upon an alternative building material, called geopolymers. Studies have shown the advantages of the material compared to concrete in durability, strength and sustainability, yet a practical building block of the material for the industry has not been implemented at scale. Unfortunately, Evans´ mother passed away before he finished school. Although Evans did not have the chance to build her a home, he realised that millions of people in his country and Africa at large faced the same problem - access to affordable housing – and that he could use the skills he had learnt during his studies to find a solution.

So, the three friends decided to act upon the idea after completing school and started working on creating samples. After initial difficulties in producing the right mix-design material, the group found support in the community of fellow experts. A post on Twitter (now X) about their challenge was answered by many helpful suggestions on how to create a working mixture.

“From there I began to believe strongly that if you are doing something, it is best to search for advice in public sources, because someone would find what's wrong with what you're doing and probably be able to help you”

, Evans explains. Furthermore, the team had to come up with an efficient way to grind the raw mineral to the particle size needed, ending up building their impact mill, after a lot of tinkering and experimentation. Along the way and also through his experience as a design engineer at an electrical car company, Evans became a real problem solver.

Right now, Evans is a BIM engineer and works with a real estate developer as an EDGE engineer in his Hometown in Ghana – EDGE is an acronym for “Excellence in Design for Greater Efficiency”, a green building certification system by the International Financial Corporation (IFC). His Co-founders have a similar background: Emmanuel Frimpong, a childhood friend and later co-worker at the electrical car company, is currently studying MSc. Renewable Energy Engineering at the University of Hull in The UK. He is particularly on a final year master's dissertation titled "Integration of Geopolymer Concrete with Renewable Energy Storage". Gertrude Akosah, Evans´ classmate and friend from school, is working as a geological engineer at the Ministry of Roads and Highways in Ghana and also works in construction, her work includes testing the strength of materials and site engineering.

The name of the start-up refers to the famous hero from Greek mythology. Theseus is mostly known for defeating the Minotaur of Crete - a powerful, human-devouring beast – by using his bravery, cleverness and determination to change the status quo, as well as self-sacrifice to save his people. As a start-up that challenges the century-old cement industry with its innovation, these qualities also apply to its founders, making the tale of Theseus a fitting analogy for the young company.

Like cement, but better and stronger

Geopolymers present a new way of making concrete materials. Here, the binder is made out of aluminosilicates – a mineral that occurs naturally in a high abundance in the earth´s crust. The production process of both binders shows a significant difference: traditional cement is produced by using limestone, which is calcium carbonate, and breaking off carbon dioxide to produce calcium oxide is essential for making cement; here, carbon emission lies in the chemistry of the process. This chemical reaction is initiated only at a high temperature of about 1000° C, which means that it is very energy-intensive.

“The size of the carbon footprint of the cement industry is apparent in the visualisation of the following fact: If the cement industry was a country, it would be the third largest contributor to emissions, which is also three times larger than the aviation industry”

, mentioned Evans. Geopolymers, however, are aluminosilicates, which do not require a chemical process to become reactive, but merely to be milled down to a certain particle size, making it an emission-free, low-energy procedure. The utilization of aluminosilicates contributes to a circular economy since 60 % of quarry or mine waste consists of the former. The rest are materials needed as concrete fillings.

Additionally, geopolymers have low thermal conductivity, meaning that the material does not transfer heat or cold as quickly as traditional concrete would. This is practical, since rooms that have been cooled, retain the cool longer than rooms with walls made from cement-based concrete, and preserve heat more as well. This translates to less energy wasted on air-conditioning/ heating up buildings.

“The core discipline of the founding team is making what a well-engineered product should be: more accessible, affordable, sustainable and responsible to the environment”

, states Evans. The idea for the innovation came to Evans when he learned that “Bowen's reaction series” describes the process of mineral crystallization from magma as it cools. It explains that different minerals crystallize at different temperatures, leading to the formation of distinct layers of minerals. Evans asked himself, whether it would be possible to reverse this process – to melt the rocks down into something that could be used for the construction of buildings. Although his initial idea proved impossible, driven by curiosity, during his research on the topic he found out about geopolymers and their advantages compared to traditional concrete and realized, that an adequate product was not available on the market yet. Geopolymers have been known since the 1970s, a term coined by Joseph Davidovits. Davidovits developed the concept to describe a class of synthetic aluminosilicate materials with a three-dimensional network structure, which can be used as an alternative to traditional Portland cement.

"I mean, if you look at history, advancement has always been about two main things: energy and materials. Whenever there has been an innovation in the source of energy and innovation of new materials, humans can push the boundaries of what they can do"

, says Evans. To summarize, geopolymers present a more sustainable alternative to cement, since the production of the material is emission-free, less energy intense and thus cost-efficient. Furthermore, aluminosilicates that geopolymers consist of can be sourced from quarry waste and mine tailings. Buildings made from these materials will not only save costs on building materials but also on costs from thermoregulation. Since no chemical extraction of the source mineral is needed, more buildings could be constructed at a faster pace, without compromising materials.

Next steps for Theseus Development

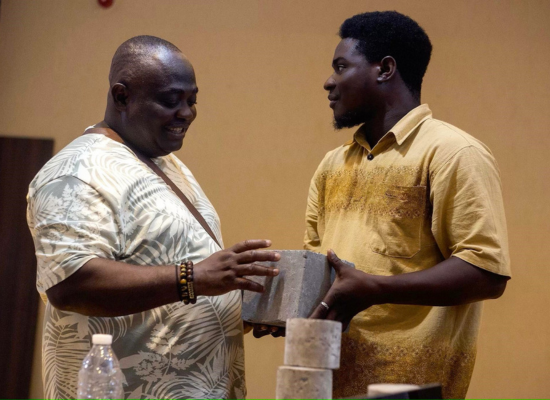

With a finished product and working technology, the start-up is now ready and seeking funding to start pilot production. Back by the African Climate Innovation Challenge, the team managed to not buy, but build the machine required to mill the mineral down to a desired particle size, showing the engineers´ creativity and determination to make their project work. The start-up is connected with GAYO, the Green African Youth Organisation, which is supporting their business development and has already connected Theseus Development with potential partners. Theseus Development is also one of our co-exhibiting and pitching start-ups at the ISC3 Investor Forum 2024.

With their innovation, Theseus Development, who joined the ISC3 Global Start-up Service in 2023, actively contributes to SDG 9 (Industry, Innovation and Infrastructure), SDG 11 (Sustainable Cities and Communities), and SDG 12 (Responsible Consumption and Production).