Weathering nature´s elements and sustainability demand

Founding Dimpora grew out of a personal drive to make outdoor gear more sustainable.

“I´ve always loved nature and the outdoors, and it didn´t sit right with me that the gear I used to enjoy these places was contributing to harming them”

, explains Mario Stucki, Co-Founder and CEO of Dimpora. During his master´s studies at ETH Zurich he saw a unique opportunity to contribute to a real change. His idea was to create membranes that could stand up to nature´s challenges without leaving a lasting impact on the environment. In his master´s project of his chemical engineering studies, which he started working on in 2013, Mario focused on creating a nanoporous, fluorine-free membrane. Seeing the potential of the project, he reached out to his university colleague, Anna Beltzung, now CTO of Dimpora and holder of a Ph.D focusing on Porous Polymer Chemistry from ETH Zurich. Together, they decided to take a leap to build the company, so Dimpora AG was officially established in 2019. Although, according to Mario, starting and growing the company has been incredibly rewarding, the young start-up had to face its share of challenges. One of the biggest hurdles was the technical complexity of creating a sustainable membrane that performs as well as conventional options.Achieving a balance between sustainability and high performance in a way that actuallymakes a difference took years of R&D and plenty of trial and error. Scaling production has also required the team to be creative and adaptable, as they had to develop the right partnerships and processes to bring their membranes from the lab to the market.

“It’s been a journey of persistence, learning, and adjusting along the way, but each challenge has strengthened our resolve to make a meaningful impact”

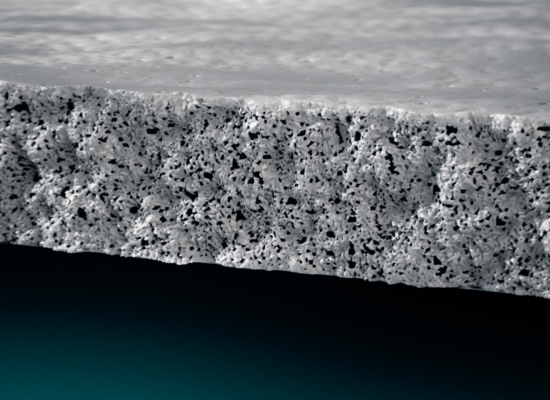

, states Mario. Now, the start-up team consists of 12 dedicated professionals. This includes specialists in research and development, operations, marketing, and sales.The name “Dimpora” can be explained as follows: “dim” stands for dimension and “pora” for pores. The membranes are microporous, meaning they are full of microscopic pores that allow the body to breathe. At the same time, these pores are small enough not to allow water in, so they keep you dry and comfortable while staying protected.

Committing to performance and the planet

The innovation at the core of Dimpora is their unique textile membranes, which are bothhigh-performance and sustainable - a combination that’s been hard to achieve in the outdoorand textile industries. Traditional waterproof membranes often rely on PFAS or otherlong-lasting chemicals, which provide the desired high performance but don’t break downin the environment. Dimpora set out to create an alternative that performs just as well but is farmore sustainable and even circular. The company achieves this through a patented process called “Corelayer Technology”: it starts with a base polymer, and then, using mineral salts, pores in the membrane are created that allow air and moisture to pass through while keeping water out. This approach allows to tune the membrane’s properties based on specific needs, such as extra breathability, added stretch, and increased waterproofness.

Dimpora´s innovation is more sustainable in comparison to current products on the market because it breaks away from the traditional reliance on toxic chemicals like Per- and polyfluoroalkyl substances (PFAS) or toxic solvents, which are widely used in the outdoor and textile industries for waterproofing but are persistent in the environment. Unlike traditional membranes, which often end up as long-lasting pollutants, Dimpora’s products are always designed with circularity in mind. What’s unique is that any polymer can be used as a raw material in the process, including biobased options, which means not being limited to fossil-fuel-derived materials.

“It’s a big step forward in Sustainable Chemistry, where we’re not just focusing on short-term performance but also on reducing the long-term environmental impact”

, explains Mario. Dimpora can also create monomaterial laminates, making recyclability way easier. Theirprocess allows them to tune the performance, whether it’s breathability, waterproofness, orstretch, without compromising sustainability. This adaptability enables the company to design membranes that match the requirements of specific brands and use cases while remaining environmentally responsible. In summary, Dimpora´s membranes offer the performance users expect but are designed to minimize environmental impact at every stage, from production through to the end of their life cycle.

Next up at Dimpora

Dimpora is at product readiness, and sales are currently their number one priority. Immediate plans are also focused on finishing their supply chain in Asia – another strategic step towards an affordable and sustainable production. Dimpora joined the ISC3 Global Start-up Service as the ISC3 Innovation Challenge finalist in July 2024. With their innovative approach, Dimpora actively contributes to SDG 12 (Responsible Consumption and Production) and SDG 13 (Climate Action).